Both Mahogany and Sapele belong to the same botanical family (Meliaceae) and share many visual similarities, leading to understandable confusion among woodworkers, architects, and clients. However, they also have important differences in appearance, durability, workability, and price that can influence your choice.

In this article, we’ll dive deep into mahogany vs sapele, comparing their key characteristics, advantages, disadvantages, and typical applications. By the end, you’ll have a clearer idea of which wood best suits your next project.

What is Mahogany?

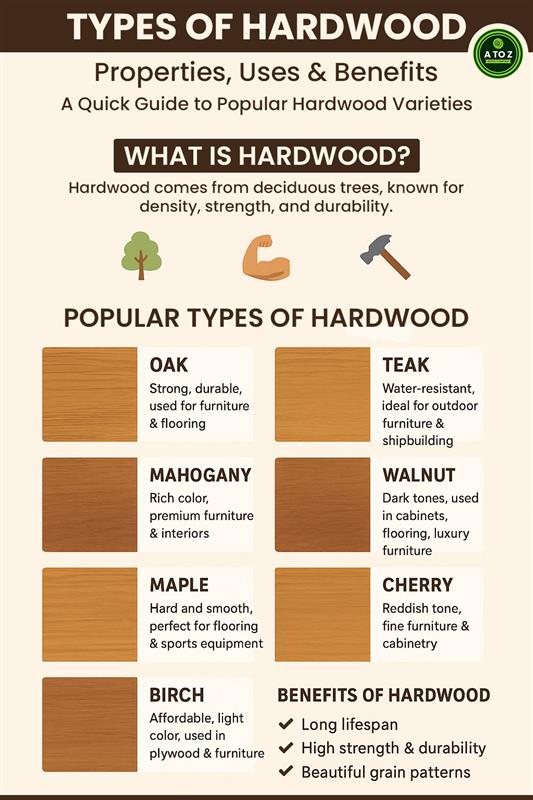

Mahogany generally refers to the wood harvested from trees of the genus Swietenia, especially Honduran mahogany (Swietenia macrophylla), which is highly prized for its deep reddish-brown color, fine grain, and stability. It is native to Central and South America, although plantations now exist in Africa and Asia.

Key features of Mahogany:

✅ Color: Starts as a light pinkish to reddish brown and darkens beautifully over time.

✅ Grain: Straight to interlocked, with a subtle ribbon figure.

✅ Texture: Fine and even, which makes it polish to a glassy finish.

✅ Density: Medium (approx. 560 kg/m³), making it relatively easy to work.

✅ Durability: Naturally resistant to decay and insects.

What is Sapele?

Sapele (Entandrophragma cylindricum) is an African hardwood, often marketed as a mahogany alternative due to similar color and grain patterns. Sapele grows widely across tropical Africa, making it more available and sometimes more affordable.

Key features of Sapele:

✅ Color: Ranges from golden to dark reddish brown, often darker and more lustrous than mahogany.

✅ Grain: More pronounced interlocking and often produces a striking ribbon stripe figure.

✅ Texture: Slightly finer than mahogany but can vary.

✅ Density: Higher (approx. 640 kg/m³), which adds to strength but may pose workability challenges.

✅ Durability: Excellent natural resistance to rot, termites, and marine borers.

Mahogany vs Sapele: Detailed Comparison

Let’s look at how mahogany and sapele stack up side by side on the most important criteria for wood buyers and designers.

| Feature | Mahogany | Sapele |

|---|---|---|

| Origin | Central & South America | Africa |

| Color | Light to medium reddish brown, darkens beautifully | Medium to dark reddish brown, sometimes with purple hues |

| Grain | Mostly straight, subtle figuring | Interlocked, dramatic ribbon patterns common |

| Density | ~560 kg/m³ (lighter) | ~640 kg/m³ (heavier) |

| Workability | Easy to cut, carve, glue, and finish | Can be harder on tools due to interlocked grain |

| Durability | Naturally resistant to decay & insects | Very durable, also resists marine borers |

| Cost | Generally higher (premium status) | More affordable but rising due to demand |

| Common Uses | High-end furniture, musical instruments, yacht interiors | Doors, windows, cabinetry, flooring, paneling |

Appearance

When choosing wood for visual appeal, both woods offer rich, warm tones. However, the difference comes down to consistency vs character.

Mahogany: Offers a more uniform look. Its straight grain and even color make it a favorite for elegant, understated luxury, especially in traditional furniture and high-end joinery.

Sapele: Famous for its dramatic ribbon-like stripes caused by interlocked grain. When quarter-sawn, sapele’s figuring becomes even more pronounced, making it perfect for statement pieces like paneling, doors, or feature furniture.

Workability

Mahogany has long been the wood of choice for fine craftsmen because of how beautifully it machines. It’s easy to plane, sand, glue, and takes stain or polish superbly.

Sapele, being denser and having interlocked grain, can sometimes tear out during planing. Sharp tools and careful technique are essential. That said, it still finishes wonderfully and is widely used in high-quality joinery.

Durability

Both are naturally resistant to rot and insects. However, sapele has an edge in environments where marine borers are a concern, which is why it’s often chosen for exterior joinery and boat building.

If maintained well (sealed and protected from prolonged moisture), both woods can last decades.

Price and Availability

Mahogany (especially genuine Honduran or “bigleaf” mahogany) has become more expensive due to stricter trade regulations under CITES. Plantation-grown mahogany helps with supply, but costs remain on the higher end.

Sapele is more abundant in African forests and tends to be 20-30% cheaper than premium mahogany. However, as demand for sustainable tropical hardwood grows, sapele’s price is also climbing.

Sustainability Considerations

Responsible sourcing is critical for both woods.

Mahogany is strictly regulated to prevent illegal logging. Always look for FSC or similar certifications.

Sapele, though more widely available, is under increasing scrutiny. Choose suppliers committed to sustainable forestry.

Which Should You Choose?

Here’s a quick guide to help you decide:

✅ Choose Mahogany if you want:

- A classic, warm, uniform appearance

- Easier machining and finishing for detailed carving or fine furniture

- A traditional luxury feel, such as for executive desks or heirloom pieces

✅ Choose Sapele if you want:

- A striking, figured appearance with ribbon stripes that stand out

- Slightly better durability in demanding conditions (like marine or heavy exterior use)

- A budget-conscious option that still delivers a luxury look

Popular Uses of Mhogany and Sapele Wood

| Application | Mahogany | Sapele |

|---|---|---|

| Furniture | Antique-style desks, cabinets, chairs | Contemporary cabinetry, wardrobes |

| Musical instruments | Guitars, pianos, violins | Guitar backs and sides, speaker boxes |

| Flooring & decking | More for interiors | Popular for both interiors and exteriors |

| Doors & windows | Luxury interior doors | High-end exterior doors, windows |

| Yacht interiors | Widely used | Used for both interiors and trim |

Where to Buy Best Quality Mahogany and Sapele Wood?

Ultimately, mahogany vs sapele isn’t about which is “better” overall, but rather which is better for your specific project goals, aesthetic preferences, and budget.

At AtoZ Wood Company, we supply premium-grade mahogany and sapele logs, sawn timber, slabs, and custom cut sizes, shipped worldwide. Whether you need bulk orders for large-scale projects or select pieces for bespoke craftsmanship, we provide competitive pricing, strict quality control, and on-time delivery to your port or site.

+237 681 25 6934

+237 681 25 6934