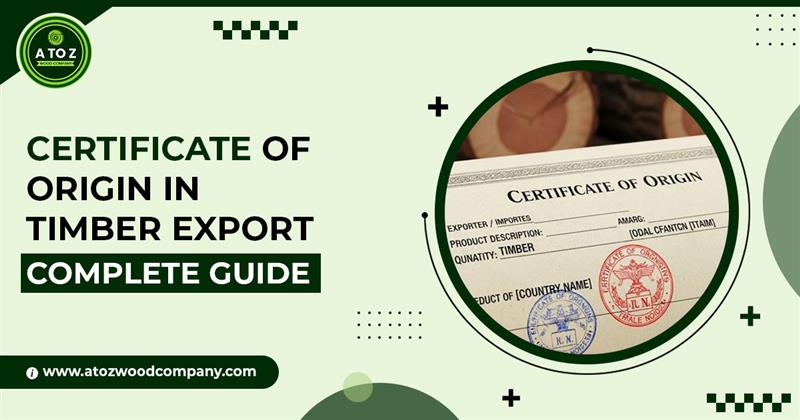

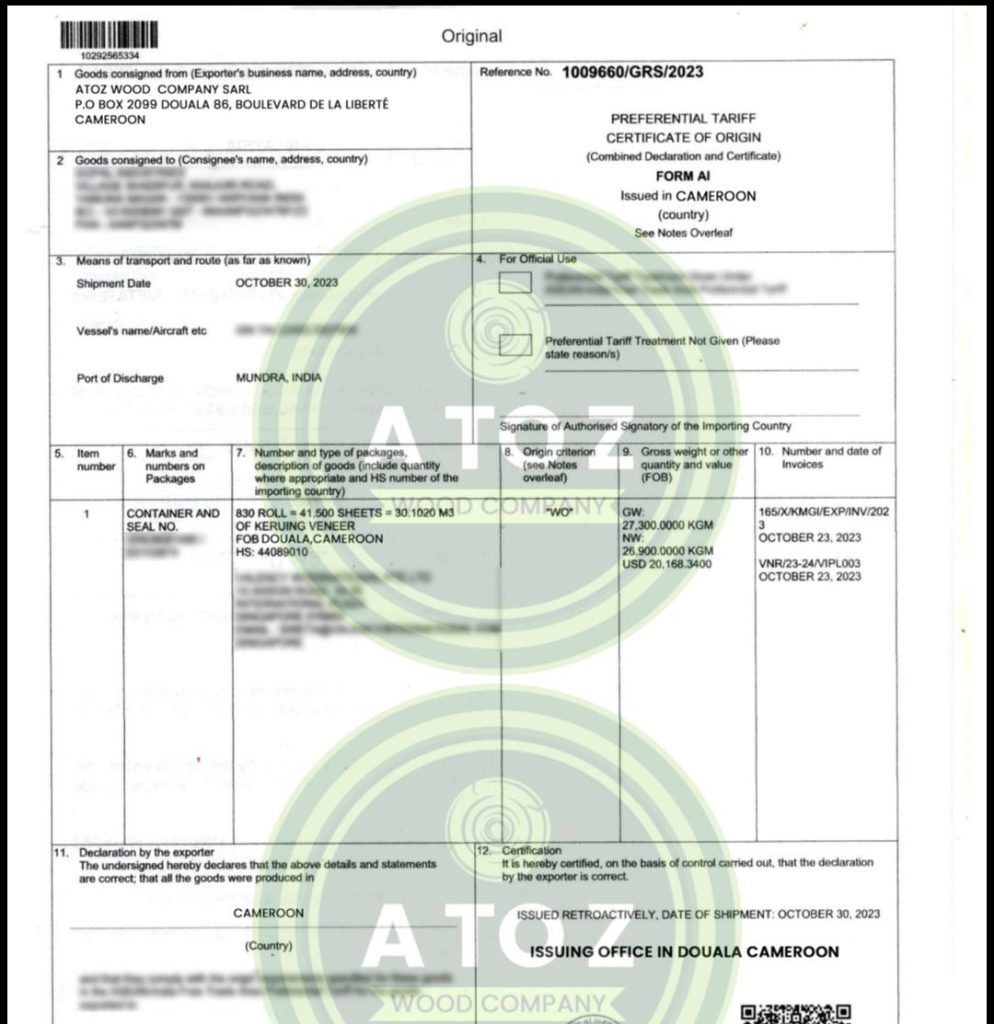

In the global timber trade, paperwork is just as important as the quality of wood itself. One such critical document is the Certificate of Origin (COO). Whether you are a timber buyer, supplier, or exporter, understanding this certificate is essential for smooth international transactions.

At AtoZ Wood Company, we ensure that every timber shipment is backed by the right documentation, guaranteeing transparency, legality, and trust. In this guide, we explain what a Certificate of Origin is, why it matters in the timber industry, and how it benefits buyers and suppliers.

✅ What is a Certificate of Origin?

A Certificate of Origin is an official document that certifies the country where the timber or wood products were harvested and processed. It acts as proof of origin for customs authorities, buyers, and trade regulators.

For timber exporters, this certificate ensures that the wood is sourced legally and meets the trade requirements of importing countries. For buyers, it serves as a guarantee of authenticity and compliance.

🌍 Why is a Certificate of Origin Important in Timber Export?

-

Customs Clearance – Many countries require a COO before allowing wood products to enter their borders.

-

Trade Tariffs & Duties – The COO helps determine applicable import taxes or preferential trade agreements.

-

Buyer Confidence – Clients can confirm the timber’s origin, ensuring it’s ethically and sustainably sourced.

-

Proof of Legality – It safeguards against illegal logging and supports sustainable forestry practices.

-

Global Recognition – A COO is recognized worldwide, making it easier to trade across multiple countries.

📑 Types of Certificates of Origin in Timber Trade

-

Non-Preferential Certificate of Origin

-

Proves where the timber comes from.

-

Used when no trade agreement reduces duties.

-

-

Preferential Certificate of Origin

-

Issued under trade agreements between countries.

-

Allows buyers to benefit from reduced tariffs or duty-free imports.

-

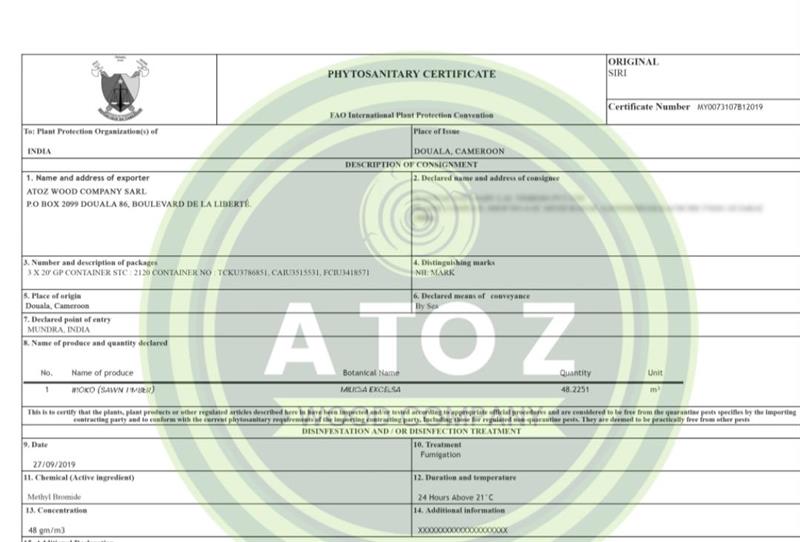

Certificate of Origin vs. Phytosanitary Certificate

While both are important, they serve different purposes:

-

Certificate of Origin – Proves the timber’s country of origin.

-

Phytosanitary Certificate – Ensures the wood is free from pests and diseases.

👉 Together, these two documents provide both legal and environmental compliance for global timber shipments.

📋 How to Obtain a Certificate of Origin for Timber Export

At AtoZ Wood Company, we follow a transparent process to ensure all documents are ready before shipment:

-

Prepare Export Documents – Invoice, packing list, and product details.

-

Apply Through Chamber of Commerce or Authorized Body – The application is submitted to an official authority.

-

Verification of Timber Origin – Proof of legal harvesting and processing is required.

-

Issuance of Certificate – Once verified, the COO is stamped and issued.

-

Attach with Shipment – The COO travels with the timber for customs clearance.

🏗️ Benefits of Certificate of Origin for Buyers & Suppliers

-

For Buyers:

-

Guarantees legal and sustainable sourcing.

-

Reduces costs through preferential tariffs.

-

Builds trust in long-term trade partnerships.

-

-

For Suppliers:

-

Ensures smooth international shipping.

-

Strengthens credibility in global markets.

-

Complies with international timber trade laws.

-

🌱 AtoZ Wood Company’s Commitment to Transparent Timber Export

At AtoZ Wood Company, we don’t just supply timber — we supply trust and transparency. Every shipment includes a valid Certificate of Origin and other essential documents to ensure our clients receive wood that is:

-

Sustainably harvested 🌳

-

Legally compliant 📜

-

Ready for global export 🚢

Our goal is to make timber trade simple, safe, and trustworthy for clients across Asia, Oceania, North & South America, Europe, and beyond.

+237 681 25 6934

+237 681 25 6934