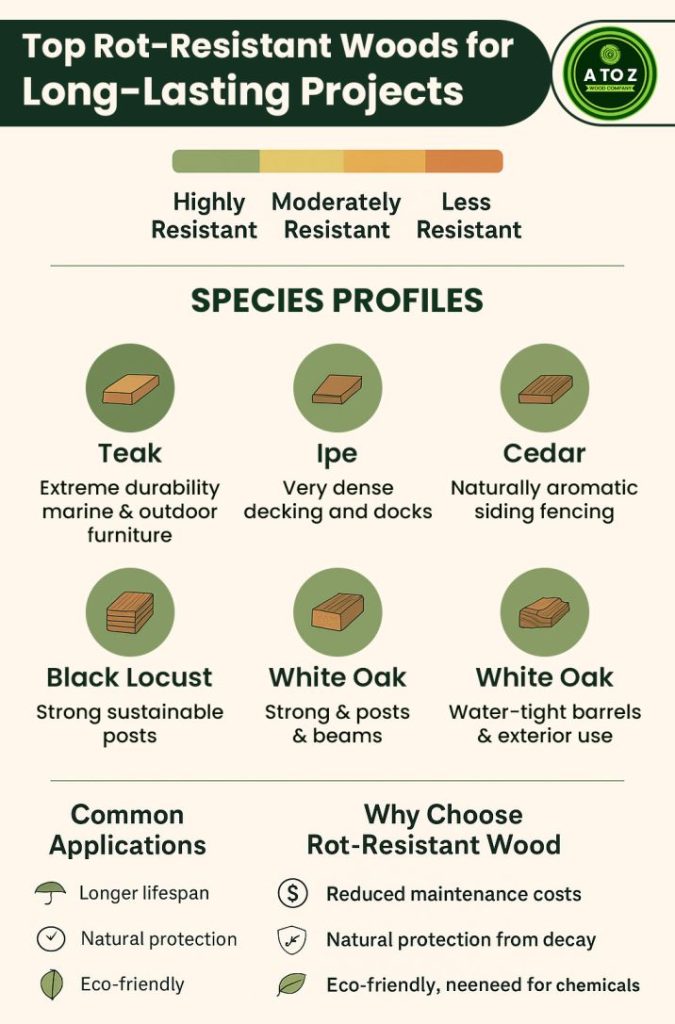

Whether you’re building outdoor furniture, decking, fencing, or a wooden structure exposed to the elements, choosing rot-resistant wood is essential. Rot, decay, and insect infestations can severely compromise the structural integrity and longevity of wood. Fortunately, some species naturally resist moisture, fungi, and insects—making them ideal for long-term outdoor use.

In this article, we explore some popular decay-resistant wood species, breaking down their features, advantages, and ideal applications to help you make a durable investment.

Why Rot-Resistant Wood Matters?

Wood rot occurs when fungi grow in moist environments, feeding on the cellulose and lignin in timber. Prolonged exposure to water, poor air circulation, and insect activity can accelerate decay. That’s where naturally rot-resistant lumber come in—they contain oils, resins, and dense structures that deter fungi and pests, ensuring extended durability without the need for heavy chemical treatments.

Best Rot-Resistant Woods Explained Visually

10 Most Durable Rot-Resistant Timber Types

1. Teak (Tectona grandis)

Teak is widely regarded as the gold standard of decay-resistant wood. Native to Southeast Asia, it’s naturally rich in oils and rubber, which protect it from moisture, insects, and fungal growth.

- Durability: Extremely high

- Common Uses: Outdoor furniture, boat decks, patios

2. Ipe (Handroanthus spp.)

Also known as Brazilian Walnut, Ipe is one of the densest hardwoods available. It scores high in Janka hardness and resists rot, termites, and moisture.

- Durability: Up to 75 years with minimal maintenance

- Common Uses: Decking, cladding, docks

3. Cedar (Western Red Cedar & Eastern White Cedar)

Cedar is lightweight yet naturally resistant to rot and insects due to its aromatic oils. It is one of the cheapest rot proof wood and an excellent choice for structural and aesthetic applications.

- Durability: 20–30 years outdoors

- Common Uses: Fences, shingles, garden beds

4. Cypress (Taxodium distichum)

Cypress contains cypretine, a natural preservative that wards off decay and bugs. It has a light golden color and stable grain structure.

- Durability: Highly rot proof, especially heartwood

- Common Uses: Siding, outdoor furniture, trim

5. Black Locust (Robinia pseudoacacia)

A U.S. native hardwood, Black Locust is exceptionally tough and rot-resistant—comparable to tropical hardwoods. It’s sustainable and fast-growing.

- Durability: 40+ years in ground contact

- Common Uses: Fence posts, decking, agricultural structures

6. Mahogany (Genuine & African)

Mahogany, especially the Genuine (Honduran) and African varieties, resists moisture and decay while offering a luxurious appearance.

- Durability: Moderate to high

- Common Uses: Boats, high-end furniture, door frames

7. White Oak (Quercus alba)

Unlike Red Oak, White Oak contains closed cellular structures and tyloses, making it watertight and decay-resistant.

- Durability: High, especially in outdoor or wet settings

- Common Uses: Whiskey barrels, exterior trim, boats

8. Tali (Erythrophleum spp.)

Tali wood, native to West and Central Africa, is known for its hardness and natural resistance to decay, insects, and marine borers.

- Durability: Very high, excellent for heavy-duty outdoor use

- Common Uses: Bridges, railway sleepers, decking

9. Redwood (Sequoia sempervirens)

California Redwood is prized for its straight grain and rot resistance, especially in heartwood sections. It’s also lightweight and thermally insulating.

- Durability: Moderate to high

- Common Uses: Siding, decks, outdoor furniture

10. Jarrah (Eucalyptus marginata)

This Australian hardwood is as tough as it gets—Jarrah is dense, resistant to rot, and nearly impervious to insect damage.

- Durability: Long-lasting even in wet climates

- Common Uses: Flooring, outdoor beams, railway ties

📈 FAQs: Rot-Resistant Lumber

Q1: What is the most rot-resistant wood?

A: Teak and Ipe are considered among the most rot proof woods in the world.

Q2: Can softwoods be rot-resistant?

A: Yes, species like Cedar and Redwood are softwoods with natural rot resistance.

Q3: How long do rot-resistant woods last?

A: Depending on exposure and species, they can last anywhere from 20 to over 75 years.

Q4: Is anti-rot wood termite-proof?

A: While not completely termite-proof, many species like Teak and Cypress are highly termite-resistant.

Where to Buy High-Quality Rot-Resistant Timber?

If you’re looking to buy premium rot-resistant timber for outdoor projects, decking, or long-lasting furniture, the best choice is to work with a trusted timber supplier and exporter. At AtoZ Wood Company, we specialize in sustainably sourced hardwoods like Teak, Iroko, Mahogany, and more—known for their natural resistance to rot and decay. We supply in bulk as well as custom orders, ensuring clients across Asia, the Middle East, Europe, and North America get durable, weather-resistant wood at competitive prices.

+237 681 25 6934

+237 681 25 6934