Are you planning a project that needs to withstand moisture, humidity, or even full water exposure? If so, marine plywood often becomes the material of choice. However, not all plywood is created equal. Understanding the different marine plywood grades is essential to ensure your project’s longevity, durability, and cost-effectiveness.

In this in-depth guide, we’ll break down:

Whether you’re building a boat, bathroom cabinets, or an outdoor deck, this guide will help you make an informed decision.

What is Marine Plywood Grade?

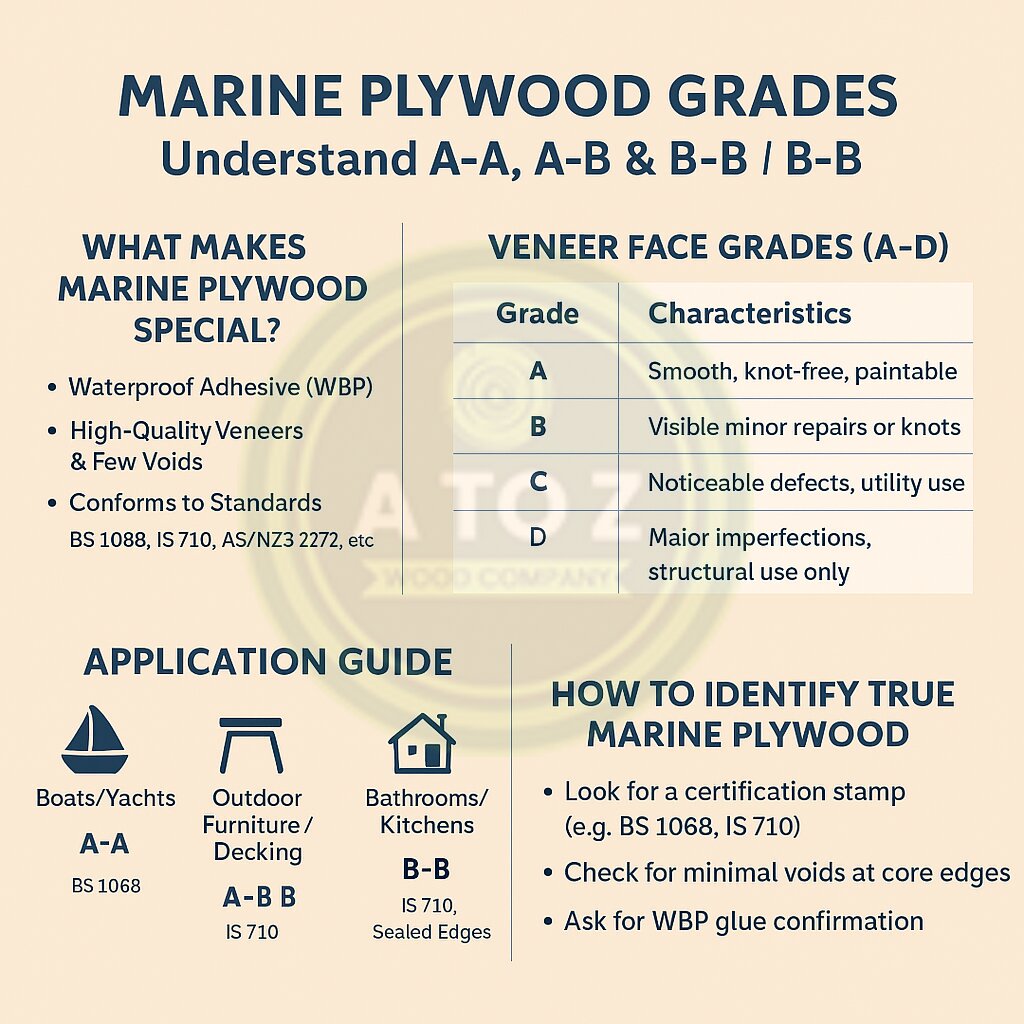

It is a high-quality plywood manufactured from durable face and core veneers, bonded with waterproof adhesives to withstand moisture, humidity, and even direct water exposure. Unlike standard plywood, marine plywood is made with fewer voids, uses higher-grade veneers, and is often treated to resist fungal attacks and de-lamination.

Key characteristics:

- Made with waterproof phenolic (WBP) glue.

- Usually has multiple plies (layers) for strength.

- Designed to minimize internal gaps, which could otherwise absorb water.

It is typically produced according to international standards such as BS 1088 (British Standard) or BS 6566, which guide the grading and performance expectations.

The plywood is graded based on the quality of its face veneers, core composition, and adhesive quality. Here, we list down some of the top-grades of marine plywood.

1️⃣ Face Veneer Grades: A, B, C, D

Face veneers are often classified similarly to standard plywood:

- A Grade: Smooth, paintable surface, no knots or patches. Suitable for visible surfaces.

- B Grade: Solid surface with minor repairs. Might have tight knots.

- C Grade: Noticeable knots and defects, usually not used for exposed surfaces.

- D Grade: Significant defects, typically for structural use where appearance doesn’t matter.

2️⃣ Typical Grades & Combinations

You’ll often see it is classified in combinations like A-A, A-B, or B-B. Here’s what they mean:

| Grade | Description |

|---|---|

| A-A | Top-quality veneers on both sides. Ideal for visible marine applications or yacht interiors. |

| A-B | One high-quality face, the reverse is slightly lower grade. Often used where one side is exposed. |

| B-B | Moderate quality both sides, usually for structural or underlay where appearance is secondary. |

For example, plywood manufactured under BS 1088 generally maintains A-A or A-B quality, ensuring both sides are of very high standard.

Adhesive & Core Considerations

The glue used is critical. True marine plywood uses WBP (Weather & Boil Proof) phenolic resin adhesives that can withstand extended boiling without delaminating.

Also, the core layers are typically made from hardwood species like Gurjan or Meranti, with minimal voids. A higher grade means:

✅ Fewer or no core gaps

✅ Better bonding between plies

✅ Increased resistance to water infiltration

Popular Standards That Define Grades

| Standard | What It Covers |

|---|---|

| BS 1088 | High-spec marine plywood for boat construction, strict on face veneer quality and voids. |

| BS 6566 | Lower than BS 1088, still moisture resistant but allows more face defects. |

| IS 710 (India) | Boiling Water Proof grade plywood suitable for marine environments. |

| AS/NZS 2272 (Australia/New Zealand) | Standards specifically for construction. |

How to Select the Right Grade?

Choosing the right grade depends on your specific project:

✅ For Boat Building

Use BS 1088 certified A-A or A-B grade marine plywood. Ensures minimal core voids and top-quality faces that can handle continuous water exposure.

✅ For Outdoor Furniture & Decking

A-B or B-B grade is usually sufficient, especially if you’re painting or sealing it.

✅ For Bathrooms & Kitchens

IS 710 or similar B-B grades work well, provided they are properly sealed and edge-treated.

✅ For Structural Applications

Focus on internal bond strength and fewer voids rather than face grade appearance.

Tips for Identifying True Marine Plywood

With many suppliers in the market, it’s important to verify what you’re buying:

✅ Ask for certification (like BS 1088, IS 710, or AS/NZS 2272).

✅ Check for consistent veneer thickness and minimal overlaps.

✅ Look for clear stamp marks indicating compliance with marine standards.

✅ Inspect edges for voids.

✅ Always buy from reputable suppliers who stand behind their product.

Where To buy the Best Grade Marine Plywood?

For professional builders, architects, and DIY enthusiasts alike, investing in the right grade can be the difference between a long-lasting masterpiece and premature repairs.

Choosing the right grade is essential to ensure your project withstands moisture, weather, and heavy use for years to come. From building boats and docks to crafting bathroom cabinetry or outdoor furniture, investing in certified plywood means you’re investing in long-term quality and safety.

At AtoZ Wood Company, we make this decision simple. As a trusted global supplier of premium timber and plywood products, we offer a full range of grades — from A-A and A-B for high-visibility projects to B-B grades perfect for structural applications. All our plywood is sourced responsibly, manufactured to international standards like BS 1088 and IS 710, and backed by expert advice to help you select the right grade for your needs.

Frequently Asked Questions

Q: Is marine plywood completely waterproof?

A: While it is highly water-resistant and built for wet conditions, it should still be properly sealed or coated to extend lifespan, especially in fully submerged applications.

Q: Can I use marine plywood indoors?

A: Absolutely. Its durability and resistance to moisture make it ideal for bathrooms, kitchens, and other high-humidity areas.

Q: Is all WBP plywood marine grade?

A: No. WBP refers to the glue line, but marine plywood also requires high-quality veneers and minimal voids. Always look for marine certifications.

+237 681 25 6934

+237 681 25 6934